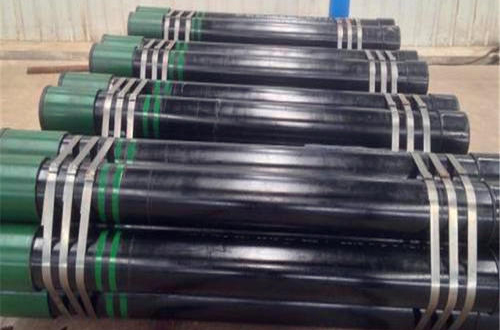

The price of oil has been rising over the past few years, and as the price has risen, so has the cost of drilling for and extracting oil. In an effort to cut costs, many oil companies are using plastic tubing instead of metal tubing in their oil wells. While this may be cheaper in the short term, it can lead to problems in the long run. Role of casing pipe: casing pipe is a special type of pipe that is mainly used for transporting and storing oil. It is corrosion-resistant, high temperature-resistant, pressure-resistant and strong. Casing pipe is usually made of stainless steel, nickel steel, aluminium alloy and other alloys. The main roles of casing pipe include transporting crude oil, natural gas, petroleum products and chemical products; storing liquid chemical raw materials and finished products; transporting fluids and gases of oil and chemical products; and transporting high temperature liquids and gases.

Material of casing pipe: casing pipe is a kind of jacket used to wrap and protect petroleum pipelines. There are many kinds of casing pipe materials, according to the different requirements of use, you need to choose different materials. Common casing pipe materials include nickel steel casing, stainless steel casing, galvanised casing, aluminised casing, tinned casing, galvanised zinc steel casing, FRP casing and so on. Construction method: the construction method of casing pipe is mainly divided into two kinds of drilling and blasting. Drilling is with the help of underground drilling machine, drilling a hole on the ground connected to the well, blasting is the explosive placed at the bottom of the well, by controlling the time and intensity of the explosion, so that the shock wave generated by the explosion through the wall of the well and the destruction of the wall of the well to form a pit.

Frequently Asked Questions: 1. What are the conditions that require the use of casing pipe? 2. What are the advantages of casing pipe? 3. What are the methods of installing casing pipe? 4. What are the precautions for the use of casing pipe? The use of plastic pipe can cause many problems for oil companies. Firstly, it is not as durable as metal piping and is more prone to damage. It is also less heat resistant, which can lead to problems with oil well equipment. In addition, plastic pipe can release harmful chemicals into the environment. All of these factors end up costing oil companies more money in the long run.